DATA INSIGHTS | CASE STUDY

Cement Plant Emissions and Permit Review in California

Data Insights to Inform Decision Making for NRDC

A joint analytical effort between AJW and the Natural Resources Defense Council (NRDC) to review and summarize emissions inventory and permit data for cement manufacturing facilities across California. This work provides critical data for stakeholders, citing current emissions profiles and regulatory landscapes for these facilities.

Our Methodology

To provide a comprehensive review, AJW followed a rigorous four-step data cleaning and evaluation process:

- Data Acquisition: Conducted an initial sweep of permitting documents and requested criteria and air toxic device-level data from the California Air Resources Board (CARB).

- Processing & Refinement: Cleaned the raw data to focus specifically on relevant air districts, plants, and associated pollutants.

- Categorization: Grouped devices by high-level type based on CARB unit lists to facilitate meaningful comparative analysis.

- Evaluation: Analyzed emissions inventory and permit limit data to identify key takeaways regarding environmental impacts.

Key Findings & Visual Insights

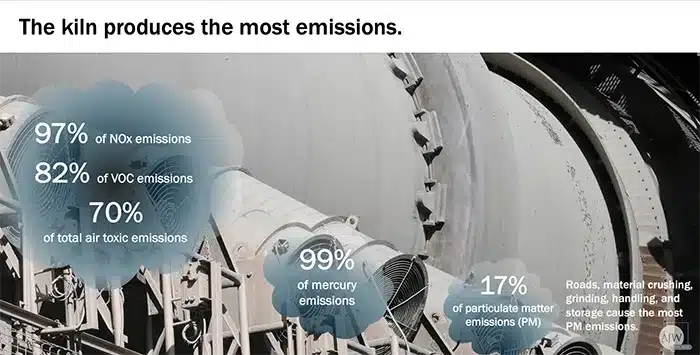

The analysis focused on the primary sources of pollution within the cement manufacturing process, with a heavy emphasis on the kiln and pyroprocessing equipment.

- The Kiln as a Primary Source: Approximately 97% of NOx emissions, 82% of VOC emissions, and 70% of total air toxic emissions at California cement plants originate from the kiln.

- Mercury Concentration: Mercury emissions are almost entirely localized to the kiln, which accounts for approximately 99% of these emissions.

- Particulate Matter (PM): Unlike gaseous pollutants, PM emissions are primarily released from roads, material crushing, grinding, handling, and storage, with only ~17% coming from the kiln.

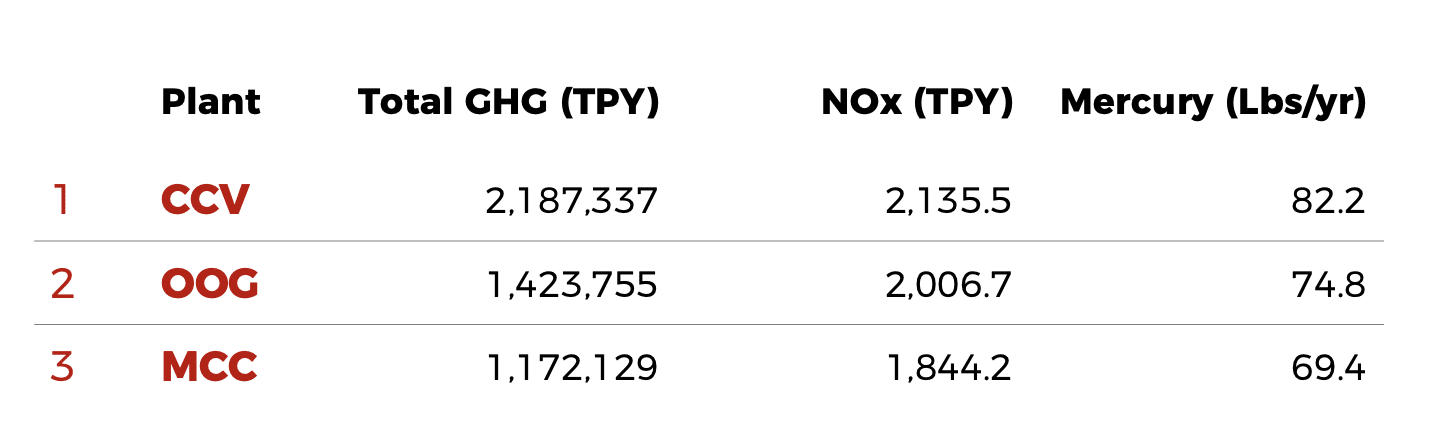

Facility Rankings (2021 Data)

Our analysis ranked the seven major California cement plants across several pollutant categories based on their 2021 facility-level inventories.

![]()

Regulatory and Permit Analysis

We reviewed individual air permits to extract data on applicable rules and fuels. The plants operate under a complex web of Federal NSPS, NESHAP, and specific Air District rules.

- Permitted Fuels: While most plants rely on coal or coke, several are permitted for alternative fuels, including Tire Derived Fuel (TDF), Biomass, and Biosolids.

- Emission Controls: Controls vary by facility but commonly include Baghouses for PM, SNCR for NOx, and Activated Carbon Injection for mercury control.

![]()

If you have questions, or would like to discuss the findings in detail, please contact us.

Presentation Download (PDF)

Please complete the form to unlock the download.

Our Services

-

Market Intelligence

-

Policy and Regulatory Analysis

-

Spatial Analysis

-

Decarbonization Strategy

-

Investment Risk Evaluation

-

Legislative, Executive, and Regulatory Advocacy

-

Policy Design